Basics of Fiber-Coupled Laser Diodes

Fiber-coupled laser diodes are a type of laser system. In a fiber-coupled laser diode, the laser diode’s output is coupled into a fiber optic cable. This is achieved by placing the fiber end very close to the laser diode or by using lenses to focus the laser light into the fiber.

Fiber-coupled laser diodes possess some advantages, including:

- The light emerging out of the optical fiber has a circular and homogenized intensity profile.

- They exhibit a symmetric beam quality.

- They possess high laser power.

- They can be coupled with other fiber optic components easily.

- It is easy to replace faulty fiber-coupled diode lasers. The process is seamless and does not require making adjustments to the device alignments.

- They make precise cuts in nanoseconds.

Types of Fiber-Coupled Diode Lasers

Different fiber-coupled laser diodes fall under two categories: single-mode and multimode lasers.

Single-mode Fiber Laser Diodes

Single-mode fiber lasers are usually transmitted via a fiber core diameter of <25 microns. This size produces a concentrated, high-intensity laser beam that can focus on a spot as small as 20 microns.

These features make this laser diode suitable for intricate laser marking, micro-machining, and precision cutting applications. Also, in nanosecond pulse regimes, single-mode laser diodes can attain significant power levels, up to 500 milliwatts.

Single-mode laser diode has applications in fiber laser seeding, gas sensing, confocal fluorescence microscopy, telecommunications, industrial manufacturing, and more.

Single-mode fiber laser diodes are available in two variants: Fabry–Pérot laser diodes or DFB (Distributed Feedback) laser diodes.

- Fabry–Pérot laser diodes: It is a type of laser diode with a special mirror structure that reflects light back and forth between two ends of the laser. Initially, it is refracted after moving into the fiber optic cable before going through total internal reflection. This results in a powerful light beam. In single-mode applications, Fabry–Pérot laser diode is utilized at various wavelengths, including but not limited to 1310 nm, 1550 nm, and 1625 nm. The emitted light falls in spectral width of 5 nm to 8 nm.

- DFB (Distributed Feedback) laser diodes: Distributed feedback is another type of laser diode with a low linewidth grating that comprises a diffraction grating. This grating plays the role of a Bragg reflector in the laser wavelength.

You may want to learn more about the difference between FP lasers and DFB lasers.

Multimode Fiber-Coupled Laser Diodes

Built on broad-area side-emitting laser diode chips, multimode fiber-coupled laser diodes are manufactured with semiconductor wafers. They feature a wider waveguide and emitting region, allowing them to generate higher levels of laser power or output power.

With broad beam diffraction, multimode laser diodes can emit light on a wider surface area. However, due to this wide emit area, the beam quality of multimode laser diodes is lower than single mode.

The shape of the laser beam depends on the ridge width of the laser chip. Note that the ridge widths of multimode laser diodes are 100 microns or more. It engages a larger volume of the material and results in more laser power, thereby reducing the risk of optical damage.

Multimode fiber-coupled laser diodes find applications in industrial, medical, and illumination.

Applications of Fiber-Coupled Laser Diodes

Fiber-coupled laser diode modules are frequently used in various applications in medical, industrial, and instrumentation. Below, we will focus on the most common industrial usage.

1. Material Processing

Laser energy is capable of altering the shape or the appearance of a material. This ability to modify a material can help business owners change designs quickly, generate products without retooling, and enhance product quality. From metals, such as iron, aluminum, stainless steel, and titanium, to non-metals, like composites, ceramics, plastics/polymers, and adhesives, the laser diode reacts well with all.

2. Cutting

Laser cutting is one of the applications. Fiber-coupled diode lasers can make precise cuts while maintaining exceptional edge quality. Having higher stability and efficiency, beam quality, easy integration, non-contact process, and faster speeds make it a top choice for precision parts that demand tight tolerances.

3. Welding

Fiber-coupled diodes are suitable for keyhole welding in various industrial processes. There are two reasons that make it useful. One, the output power of fiber lasers is between 500 W to 10 kW. And two, they can gain focused spot sizes between 40 and 800 μm even if the working distance is huge.

4. Engraving

Fiber lasers can leave permanent marks on surfaces like some plastics and metals. During the procedure, the laser light uses a focused light beam and transmits it to the material surface to make a mark. This technique helps in creating permanent marks with precision.

The Role of Fiber-Coupled Laser Diodes in Laser Cutting

Fiber-coupled laser diode has a significant application in laser cutting, let’s focus on it.

The laser technology uses stimulated radiation to produce a laser beam. A laser diode then releases light to send it to the fiber optic cables for amplification. When this laser light comes in contact with the surface of the subject material, it penetrates the latter and transforms itself into heat energy. This heat generated is responsible for making the surface melt.

Generally speaking, fiber-coupled diode is useful in laser cutting due to the following four characteristics:

- Power stability: FCLD has stable output power, which is essential for laser cutting as it ascertains consistent results.

- Low noise: Low noise levels protect operators from musculoskeletal disorders and noise-related stress.

- More advanced beam pointing stability: This implies that the laser beam will make precise laser cuts.

- Locating the laser remotely: This helps in improving the safety and stability of the laser cutting systems.

In laser cutting, air assist also plays a key role in enhancing the cutting speed as well as the quality of the cut. So, as the technicians use an air stream at a high speed parallel to the laser beam, the air removes the molten metal and ascertains that the cut is of high quality.

Multiwavelength of Fiber-Coupled

Optical fiber sources such as fiber-coupled diode lasers can simultaneously emit light at multiple wavelengths. To elaborate, the wavelength of the laser diode module falls directly within the infrared part of the spectrum, i.e., between 780 nm and 2200 nm.

While this portion is not visible to the naked eye, it can react with different kinds of materials. It is the shorter wavelength range that allows the laser light to penetrate them easily. The materials include metals, rubber, and plastics, making the multiwavelength feature highly useful in a wide variety of material processing applications.

Some multi-wavelength laser modules can be tailored up to wavelengths from 1mW to 5mW. This alteration of wavelength is done either by adjusting the temperature or stretching the laser cavity. It can also be achieved by adjusting the current to the seed laser.

A few advantages of these multiwavelength diode lasers are low cost, compact size, and little insertion loss.

Choosing the Right Fiber-Coupled Laser Diode

To achieve the right output power, it is important to pick the right fiber laser system. In the case of fiber-coupled diode lasers, below are a few considerable factors.

1. Wavelength Range

The wavelength of a laser diode decides the type of material it is capable of cutting or engraving. For instance, CO2 lasers possess a wavelength of 9.6 and 10.6 micrometers (μm), perfect for cutting and engraving non-metallic surfaces such as wood, acrylic, and paper. Fiber lasers, on the other hand, with a wavelength of 1.06 micrometers, can cut or engrave metals such as steel, aluminum, and copper.

2. Power Output

The power output of the laser diode improves cutting speed and depth. A higher-power laser diode can not only cut material faster but also deeper in comparison to a laser diode with lower power. But higher power diode lasers are expensive.

3. Beam Quality

The quality of the laser beam affects the accuracy and precision of the cut. A higher beam quality produces better results. Beam quality is measured in the M2 factor. When the M2 factor is low, beam quality is high.

4. Fiber Type

There are two primary types of fiber used in fiber-coupled diode: single-mode fiber and multi-mode fiber. Single-mode fiber possesses a smaller fiber core diameter and can transmit more power over longer distances. Whereas in a multimode fiber laser, the fiber core diameter is larger.

5. Cooling Method

One can cool a fiber-coupled laser diode using either air or water. Air cooling is the most common cooling method. Air cooling increases the surface area of the object you want to cool. For instance, if you add cooling fins to the laser diode, it will increase the heat transfer rate.

Another way used to cool semiconductor laser diodes is by keeping the laser bar on a thermoelectric cooler (TEC). The TEC uses the Peltier effect to cool down the laser.

On the other hand, water cooling is more effective; however, it is expensive and also complicated.

For more information on cooling laser diodes, read this article.

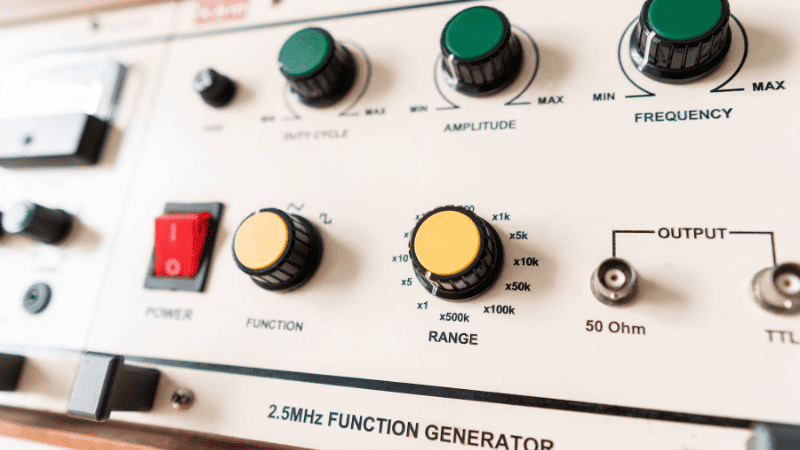

6. Control Options

Fiber-coupled diode lasers have two options for controlling the device. One is an internal controller, and the other is an external controller. A few examples of internal controllers include an on-board pulse generator or a function generator.

A DC or sine wave voltage source is an example of an external controller. It is up to the user to choose the type of controller: internal or external.

A few ways to control fiber-coupled laser diodes:

- Adjust the amount of electricity flowing through the laser diodes

- Utilize an internal generator to make signals to change the laser’s intensity or create short bursts of laser light.

- Start an internal signal generator using a signal from an external generator.

- Adjust the remote TTL signal source to produce continuous pulses that last 100 microseconds.

- Use the internal function generator to create the quasi-CW pulses.

7. Diode Packaging

Right packaging helps protect the laser diode from humidity, dust, outgassing, and mechanical damage. Conducting heat away is an effective way to cool smaller sealed packages; however, for bigger ones, active cooling using a special device called a TEC (Thermoelectric Cooler) or water cooling works better.

Handling diode packaging requires one to understand the following:

- Before opening the package, keep it in a room for a minimum of 4 hours to allow it to achieve thermal equilibrium.

- Do not keep glues, solvents, plastics, and heat conductive paste near the laser diode

- Use the current regulated laser diode drivers specially manufactured for laser diodes only.

8. Additional Tips for Choosing a Fiber-Coupled Diode Laser

Before a business owner decides to buy a fiber-coupled laser diode, he is suggested to:

- Consider the type of material you need to cut or engrave.

- Consider the thickness of the material you need to cut.

- Consider the total size of the fiber optic cable employed to achieve coupling efficiency.

- Consider your budget.

FAQs

1 – What is the Difference Between Fiber-Coupled Diode Lasers and Normal Diode Lasers?

Fiber-coupled diode lasers are lasers that employ an optical fiber to transmit laser light to their target. Normal diode lasers, on the other hand, are composed of vertically stacked diode bars.

2 – If the Output Beam of Multimode Laser Diodes is 200 to 300 μm, Can You Characterize it as a Gaussian Beam?

No, the resultant beam is not a Gaussian beam. However, if the intensity profile falls closer to the Gaussian distribution, one can apply Gaussian beam propagation principles.

3 – What is the Main Difference Between Free Space and Fiber-Coupled?

In free space, diode lasers use air, vacuum, or outer space as a medium for transmitting light. But fiber-coupled lasers couple the light they produce. This fiber coupling ensures that the light falls in the target.

4 – Can You Call Fiber Laser Diode?

Yes, a fiber laser is a diode laser; it is a diode-pumped solid-state laser(DPSSL). These diodes are semiconductor diodes functioning as a laser source emitting light into a fiber composed of phosphate glass or silicate. After absorbing the light, it converts it into laser light.

Conclusion

Fiber-coupled laser diode is a powerful semiconductor. Understanding how it works and helps in different industries is a great approach to deciding what will work for you. It is a promising technology that has the potential to revolutionize how different industries will work in the future.

Unleash the Power of Fiber Lasers with Baison Laser!

Baison Laser is your go-to company for laser welding, marking, and cutting machines. Our fiber laser machines are manufactured with advanced techniques and are highly efficient. These are easy to operate, work at a faster speed, and promise higher output power and precision in each go. Contact us for a free sample. Our friendly experts will ensure you choose the right machine.