Both plasma cleaning and laser cleaning have pros and cons. In this article, we’ll explain these cleaning methods in greater detail to help you decide which is the best method for your needs.

What Is Plasma Cleaning?

Unlike other surface cleaning methods, a plasma cleaning process uses an ionized gas called plasma to remove organic surface contaminants (e.g., dust, oil, and paint). This process helps improve the adhesive bonding of certain materials.

Just to be clear, the word plasma in plasma cleaning doesn’t refer to a specific substance. Plasma is often described as the fourth state of matter because it contains a mixture of charged electrons and ions that drift freely among the nuclei of the atoms.

Plasma treatment has a wide range of cleaning applications in different industries. It can remove organic contaminants from the surfaces of ceramics, glasses, metals, and plastics.

While the pandemic negatively impacted every industry, the opposite is true for the industry of plasma cleaners. The industry experienced staggering demand and growth during the global COVID-19 pandemic.

This sudden surge in annual growth will return to its usual levels once the pandemic is over. According to the Business Research Insights report, the size of the global plasma cleaner market is set to grow by $672.91 million by 2031.

What Is Laser Cleaning?

The potential great benefits of laser cleaning over other surface cleaning methods have led to its adoption in different industries, including the electronics industry. According to the latest report from Mordor Intelligence, the market size of the laser cleaning industry is projected to grow from $0.78 billion in 2023 to $1.53 billion by 2028.

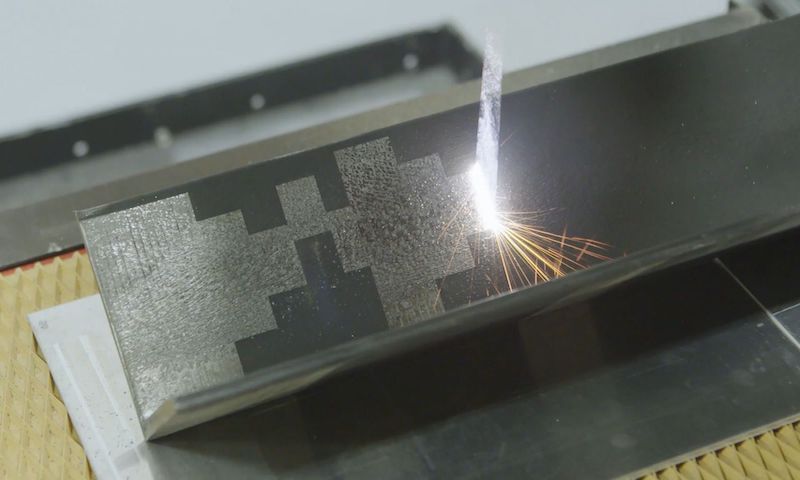

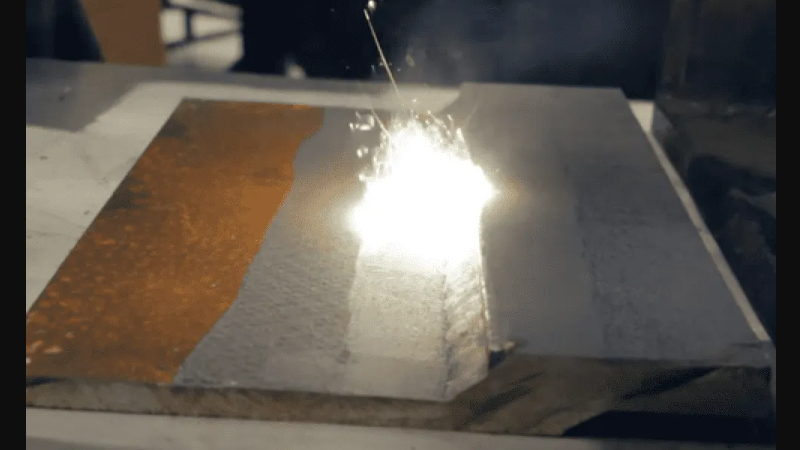

Laser cleaning, also referred to as laser ablation, is usually efficient and environmentally friendly. Many manufacturers often use it to replace abrasive techniques (e.g., dry ice blasting) and chemical cleaning.

Laser cleaning relies on high-intensity laser light to remove contaminants, such as dirt, grease, paint, and rust, from surfaces. When the intense laser beam of this laser technology hits the organic contaminants, they immediately absorb the energy and vaporize into dust, without damaging the underlying material.

Do You Have Any Questions?

Let Us Solve Your Problem

The Pros and Cons of Plasma Cleaning and Laser Cleaning

Laser cleaning and plasma cleaning are both versatile surface cleaning methods, each with its own advantages and limitations. To help you make an informed decision, here are the pros and cons of each method:

Plasma Cleaning

Pros:

- Plasma Cleaning Speed: In general, it can fully clean and activate the surface of a material within a few minutes.

- Useful in Different Applications: You can use it in a wide range of applications and materials. It’s a good option for removing grease, mineral oils, and other organic residues from ceramics, glasses, plastics, and semiconductors.

- Leaves No Residue: If you require surfaces that have minimal to zero residue, then you need a plasma cleaner.

Cons:

- Additional Costs: A plasma cleaner requires additional equipment, which can increase your expenses.

- Knowledge and Training: To ensure optimal results and safety, the person operating the machine should have the proper training and knowledge.

Laser Cleaning

Pros:

- Incredibly Precise: Laser cleaning equipment can remove surface contaminants and coatings with pinpoint accuracy.

- Non-Destructive Method: There’s a relatively low chance that laser cleaning will cause any damage. That’s because the object’s surface and the machine don’t come into contact during the whole process.

- Efficient and Safe: The laser cleaning machine can accurately control the laser beam’s intensity and range. As a result, it’s relatively safe for the machine’s operator.

Cons:

- High Cost: Laser cleaning equipment has a high upfront and maintenance cost. This makes it less accessible for small businesses or people on a tight budget.

- Application and Range Limitations: Laser cleaning is usually more suitable for materials with a harder surface. When it comes to large or deep-seated contaminants, it might have a hard time removing them. You may be interested in using lasers to remove dirt from artwork.

The Difference Between Plasma Cleaning and Laser Cleaning

There are several key differences between laser cleaning and plasma cleaning. Let’s go over some of them to help you decide which one works best for your needs.

The speed of laser and plasma cleaning methods is determined by several factors, such as cleaning parameters (e.g., the spot size of the laser beam), power and type of laser, thickness, and type of contaminants, and the surface size of the area to be cleaned.

Cleaning Speed: In general, laser cleaning is faster than plasma cleaning, which usually has a slow duty cycle. This means a plasma cleaning machine spends more time and energy on moving mechanical parts and less on cleaning. The slow duty cycle reduces output power, which can affect the machine’s efficiency and cleaning speed.

Cleaning Quality: Neither of the two cleaning methods is inherently better in terms of the quality of their cleaning performance. In fact, there might be instances wherein you might use both to achieve your desired result. However, there are manufacturers who find it difficult to remove oxides from metals, which plasma cleaning usually leaves behind.

Surface Cleaning Precision: In most cases, laser cleaning is remarkably more precise than plasma cleaning. One good reason for its higher precision is that the machine can produce a highly focused laser beam on specific contaminants or areas to be cleaned. This makes it a valuable tool when cleaning complex, fragile, and soft surfaces.

Equipment and Maintenance Costs: Plasma cleaning machines are typically more affordable than their laser counterparts. Laser cleaning machines are expensive to purchase and maintain (due to their high energy consumption).

However, it’s also important to note that plasma cleaners may require additional equipment and tools. This can quickly increase your expenses, which can prevent you from taking advantage of its benefits.

A Quick Overview: Laser Cleaning vs. Plasma Cleaning

| Laser Cleaning | Plasma Cleaning | |

| Speed | Relatively faster | Tends to be slower because of its mechanical movements, which are slower than Galvo mirrors |

| Cleaning Quality | Efficiently removes surface contaminants and coatings | Can leave behind stubborn carbonized residues |

| Precision | Highly precise | Less precise |

| Application | Can remove a wider range of contaminants, including rust and oxides | More effective in removing organic contaminants, such as oils and polymers |

| Costs | More expensive | More affordable |

Do You Have Any Questions?

Let Us Solve Your Problem

Which Is Better for You – Plasma Cleaning or Laser Cleaning?

Ultimately, it’s up to you to decide which of the two cleaning methods will work best for your budget and requirements. Each method offers unique advantages and limitations, which you need to carefully consider.

Here are some factors you can consider when choosing between laser cleaning and plasma cleaning:

1. Type of Contaminants

Let’s take a look at where laser cleaning and plasma cleaning shine the brightest.

Laser cleaning is more suitable for:

- Removing rust

- Electronic device production

- Medical applications

- Military equipment and vehicle maintenance

- Mold cleaning

- Protection of heritage monuments, sculptures, and buildings

- Surface treatment

Plasma cleaning is more suitable for:

- Extremely fine cleaning of metal surfaces

- Surface cleaning and preparation of a variety of materials, including ceramics, general glass products, plastics, and rubbery materials

2. Level of Cleaning Precision

Laser cleaning has become an essential process in a wide range of industries, especially those that require the final product to be completely pure. Aside from its precision, this method makes it easier to reach the corners and nooks of objects with complex designs.

However, this doesn’t mean plasma cleaning machines can’t offer a good level of precision. This, of course, depends on several factors, including equipment design, gas selection, and parameter optimization.

3. Quality of the Cleaned Surface

Throughout the years, there’s been an increasing number of companies that require more advanced and refined production methods. This is where laser cleaning has become a popular choice among many manufacturers. Unlike conventional methods, laser-based cleaning solutions don’t usually cause potentially harmful vapors, too much waste production, or damage fragile surfaces.

So, when you’re choosing the best surface cleaning methods, think of the desired finish or quality of the material’s cleaned surface.

4. Maintenance and Reliability

Monitoring the maintenance costs of each surface cleaning method is an important part of your business’s financial health. By knowing the costs of keeping it running correctly, you can prepare better and make more informed decisions about repairs and replacements.

Let’s take plasma cleaning as an example. Some of the costs associated with it include the following:

- Downtime costs

- Contracts for routine adjustments, cleaning, and inspections

- Repair or replacement of components (e.g., electrodes, power supply units, and filters)

Conclusion

So, which is better, laser cleaning or plasma cleaning?

The answer is: It depends. There’s no one-size-fits-all answer since both surface cleaning methods have their advantages and disadvantages.

When thinking of buying any surface cleaning equipment, think about your budget, intended purpose, the type of contaminants, and the surface of the material it’s going to clean, among others.

Buy the Best Laser Cleaning Machine From Baison Laser Today!

Effective removal of organic contaminants and surface preparation starts with the best cleaning machine. Baison Laser offers one of the most innovative and high-quality laser cleaning machines in the industry at a low cost. Our machines can provide you with customized requirements. Click here to request an instant quote.