Introduction to Stainless Steel Laser Cutting

Laser cutting offers numerous benefits for stainless steel, including precision, efficiency, and versatility, making it a popular choice in various applications. Now let’s take a comprehensive look at laser cutting stainless steel.

Understanding the Basics

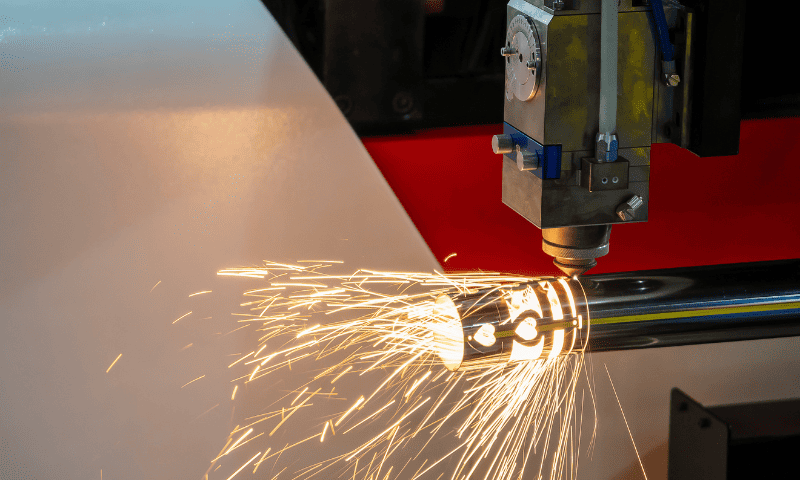

Stainless steel laser cutting is a precise and efficient process that utilizes a high-powered laser beam to cut through stainless steel sheets. The laser beam melts and vaporizes the stainless steel material, focusing on a specific point and resulting in a clean and accurate cut. This process is highly controlled and can achieve intricate designs with sharp edges and fine details.

It’s no wonder laser cutting is widely used in industries like automotive, aerospace, and manufacturing. With laser technology at your fingertips, you can unleash its power to create intricate designs and patterns on metal surfaces. Think laser engraving, etching, and even annealing. The possibilities are endless!

Why Laser Cut Stainless Steel?

Laser cutting is particularly advantageous for stainless steel due to several reasons. Firstly, stainless steel is a durable and corrosion-resistant material commonly used in various industries, including architecture, automotive, and aerospace. Laser cutting provides a precise and efficient method for shaping and cutting stainless steel, ensuring high-quality results.

Additionally, laser cutting is a non-contact process, meaning there is no physical contact with the material, reducing the risk of contamination or damage. Moreover, laser cutting allows for complex and intricate designs, making it ideal for creating customized stainless steel components or decorative pieces.

So whether you’re shaping layer nozzles or crafting metal masterpieces, laser metal cutting is your go-to technique. Ready to dive into the world of laser cutting stainless steel? Let’s get started!

Choosing the Right Laser for Stainless Steel Cutting

Fiber lasers are an excellent choice for stainless steel cutting, thanks to their high power and efficiency. These lasers are commonly used in the industry due to their ability to deliver precise and clean cuts. CO2 lasers can also be used for stainless steel cutting, but they are better suited for thicker materials. For more information, you can read the article written by S. Stelzer.

CO2 Lasers

CO2 lasers are commonly used for stainless steel cutting due to their ability to efficiently cut thicker materials. These lasers produce a high-power beam of infrared light that is well-absorbed by stainless steel, resulting in efficient cutting.

CO2 lasers offer versatility in terms of power and beam quality, allowing for precise and clean cuts on stainless steel. They are suitable for a wide range of stainless steel thicknesses and can handle both thin metal sheets and thicker materials, making them a popular choice for industrial applications.

Fiber Lasers

A fiber laser cutting machine is another option for stainless steel cutting, offering several advantages over traditional cutting methods such as CO2 laser cutter, plasma cutting and waterjet cutting. Here is a comparison of laser cutting and plasma cutting. Fiber laser machines use a solid-state laser source, which generates a laser beam through the amplification of laser light in a fiber optic cable. The fiber laser cutter is highly efficient and provides excellent beam quality, resulting in precise and high-speed cutting of stainless steel.

Operating costs for fiber laser cutter are lower because of their electrical efficiency and solid-state construction. Fiber lasers are particularly well-suited for thin to medium thickness stainless steel sheets, offering superior cutting speed and energy efficiency compared to CO2 lasers. Fiber laser cutter also has a smaller footprint, making them a more compact and cost-effective option for stainless steel cutting.

To determine the most suitable laser for specific stainless steel cutting needs, it is advisable to consult with experts in the field. They can provide valuable insights based on their experience and knowledge of different laser systems.

Pre-Processing for Stainless Steel Laser Cutting

Here are some best practices to follow when pre-processing stainless steel for laser cutting.

Preparing the Material

Accurate measurement and marking of the stainless steel plates are crucial for achieving precise cuts. Before laser cutting, it is essential to properly clean the surface of the stainless steel to ensure optimal results. Applying an anti-spatter coating can help prevent molten metal from adhering to the surface during cutting. To minimize vibrations during cutting, it is important to secure the material firmly in place using clamps or fixtures.

Setting up the Laser Cutting Machine

When setting up the laser cutting machine for stainless steel, it is necessary to adjust according to the plate thickness. For thin plate workpieces, such as sheet metal or valve plates, adjusting the laser power and speed settings may be necessary to achieve desired results. On the other hand, thick plate or alloy materials might require higher power levels and slower cutting speeds.

By following these pre-processing steps and best practices, you can ensure better results when laser cutting stainless steel. Remember that each project may have specific requirements, so it’s important to experiment with different settings if needed while considering factors like pressure nitrogen usage for improved performance.

Now that we have covered preparing materials and setting up your laser cutting machine, let’s move on to the next stage: the actual cutting process.

The Cutting Process

During laser cutting, the computer-controlled machine follows programmed instructions to create intricate shapes and designs accurately. Assist gases such as nitrogen or oxygen are often used to blow away molten metal and debris from the cut area. The speed at which the laser moves across the material affects both cutting quality and processing time.

Executing the Cutting

The cutting process begins by inputting the design file into the laser cutting machine’s software. The machine then uses the laser beam to precisely cut the surface of the stainless steel material according to the design specifications. It is focused on a focal point, melting and vaporizing the stainless steel as the laser beam moves along the cutting path.

The cutting speed and power of the laser beam are carefully controlled to ensure a clean and accurate cut. The cutting process is automated and highly efficient, allowing for the creation of intricate shapes and designs with minimal material waste.

Monitoring and Adjusting the Parameters

To ensure optimal cutting results, it is important to monitor and adjust various parameters throughout the process. These parameters include:

- Laser Power: The power of the laser beam determines its ability to melt or vaporize the stainless steel. Adjusting this parameter allows for precise control over the depth of the cut.

- Cutting Speed: The speed at which the laser moves across the material affects both cut quality and processing time. Finding the right balance is crucial to achieving clean cuts without compromising efficiency.

- Assist Gas Pressure: Oxygen or inert gas like nitrogen is commonly used as an assist gas during laser cutting and engraving. Controlling the cutting gas pressure helps in blowing away molten metal and debris, ensuring a cleaner cut and engraving process.

- Focus Position: Properly aligning the focus position of the laser beam ensures accurate engraving and cutting results. A narrow kerf width can be achieved by adjusting this parameter correctly.

- Material Thickness: Different thicknesses of stainless steel require adjustments in cutting parameters for optimal results. Thicker materials may require slower speeds and higher power settings, while thinner materials may require faster speeds with lower power settings.

By carefully monitoring and adjusting these parameters, laser cutting machines can deliver precise cuts on stainless steel with minimal deformation or markings.

Post-Processing after Cutting

After laser cutting stainless steel, it is important to perform post-processing steps to ensure optimal results. Here are some best practices for post-processing.

Inspecting the Cut Quality

- Thoroughly examine the cutting edge quality of the stainless steel after laser metal cutting, laser etching, laser annealing, and nitrogen cutting to assess the quality of the cut.

- Look for any slag or burrs that may be present on the edges after laser etching, laser metal cutting, or laser engraving machine processes.

- If precision is crucial, use deburring tools or sanding to achieve the desired edge smoothness.

Cleaning and Finishing

- Remove any slag or burrs left on the edges of the laser metal cutting for a smooth finish.

- Clean off the residue from assist gases to ensure a clean final product.

- Consider using auxiliary gas during laser engraving and cutting with a fiber laser to minimize contamination and improve results.

Proper handling and storage of the cut stainless steel pieces are also essential. You should handle the pieces with care to prevent damage or distortion, and then store them in a suitable environment to avoid contamination or corrosion.

Common Mistakes and How to Avoid Them

Avoiding common mistakes is crucial for achieving optimal results. Here are some key points to consider.

Error in Parameter Setting

- Insufficient power and speed settings in laser engraving and fiber laser cutting can lead to incomplete cuts or slow processing times. You can find the perfect set up for them through this article. Make sure to adjust the power and speed settings appropriately for the thickness and type of stainless steel being cut.

- Inaccurate focus adjustment may result in inconsistent cutting depths or poor cutting quality. Take the time to properly calibrate and align the laser focus for precise cutting.

- Neglecting regular maintenance of the laser machine can cause performance issues and reduce its lifespan. Follow manufacturer guidelines for cleaning, lubrication, and inspection to ensure smooth operation.

- Failing to optimize cutting parameters for specific stainless steel grades can yield subpar results. Different grades of stainless steel require varying speed, frequency, energy, and assist gas settings. Be mindful of these variations.

Improper Material Handling

- Problems can arise from improper material handling during laser cutting processes. Ensure that the stainless steel sheets are securely positioned and aligned before initiating the cutting process.

- Advantages of using multiple passes: When dealing with thicker stainless steel sheets, it may be necessary to perform multiple passes with adjusted settings rather than attempting a single pass at high speed.

- Pointers on assist gas usage: The choice of auxiliary gas (such as air or oxygen) affects the quality of the cut by influencing oxidation levels and energy transfer during the process.

- Oxide removal: After laser cutting, oxide residue may form on the surface of stainless steel due to heat exposure; this should be removed promptly using appropriate methods.

By being aware of these common mistakes and following best practices in parameter setting, material handling, and maintenance, you can enhance your laser cutting process for stainless steel while achieving desired outcomes with efficiency and precision.

Why Choose Baison Laser Machines for Stainless Steel Cutting

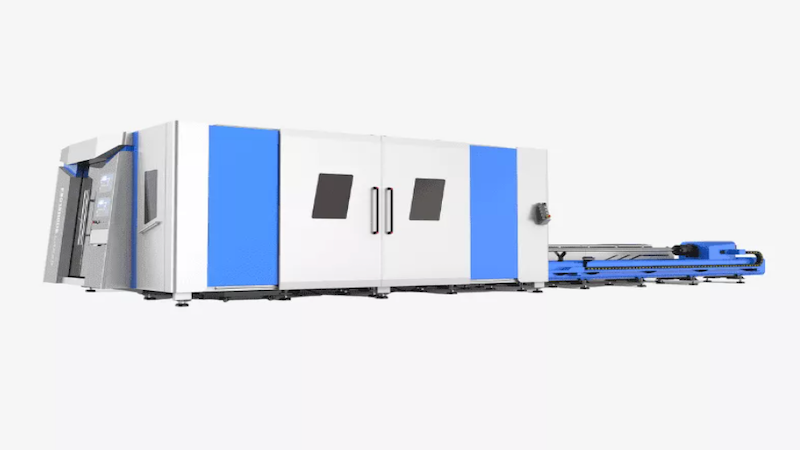

Choosing the right machine is crucial for achieving precision and efficiency. Baison Laser stands out from the competition due to our unmatched precision and efficiency in stainless steel cutting applications.

Unmatched Precision and Efficiency

Baison Laser Machines offer high-quality, reliable, and efficient solutions for stainless steel cutting applications. Our cutting-edge technology ensures precise cuts with minimal material wastage, saving you time and money.

Exceptional Customer Support

When you choose Baison Laser Machines, you can count on our exceptional customer support. We provide comprehensive training to ensure that you maximize the capabilities of our machines. In case of any issues, our troubleshooting assistance will get you back up and running quickly. We have spare parts readily available to minimize downtime.

Versatility for Different Applications

Baison Laser Machines are equipped with advanced features such as automatic focusing systems and intelligent control interfaces. This versatility allows you to handle various stainless steel cutting requirements, whether it’s thin sheets or thick plates.

With a wide range of models available, Baison offers options suitable for various production volumes and budget requirements. Whether you’re a small business or a large-scale manufacturer, there is a Baison Laser Machine that fits your needs perfectly. Click through the product list to find the best equipment.

By following these guidelines and utilizing Baison Laser Machines’ expertise in stainless steel cutting, you can contact us to confidently tackle any project with efficiency and precision.

FAQs

Can I use any type of laser machine for cutting stainless steel?

No, it is important to choose a laser machine specifically designed for stainless steel cutting to ensure accurate results.

Why should I choose Baison Laser Machines over other brands?

Baison Laser Machines offer advanced technology, precision engineering, and a reputation for reliability in stainless steel cutting.

Can I achieve intricate designs with laser cutting in stainless steel?

Yes, laser cutting allows for precise and intricate designs to be achieved on stainless steel materials.

Conclusion

By now, you should be well-equipped with knowledge of the process and best practices of laser cutting stainless steel. What part of this process intrigued you the most? Let us know in the comments. If you’re ready to experience precision and efficiency with Baison Laser machines, our team is here to assist you immediately.