Introduction to Sheet Metal Laser Cutting Machines

Advanced sheet metal laser cutting machines are the latest machinery in manufacturing techniques. These cutters utilize laser technology to slice through various metals quickly and accurately. With their ability to create intricate designs and complex shapes, it’s no wonder they’re widely used in industries like automotive, aerospace, and electronics for processing equipment.

Understanding Laser Cutting

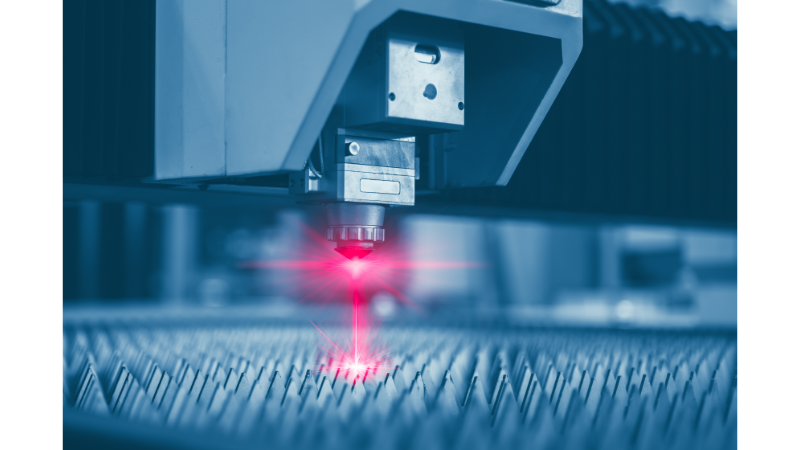

Laser cutting is a precise and efficient method of cutting various materials, including cutting sheet metal. It involves using a high intensity laser beam from a laser tube to melt, burn, or vaporize the material, resulting in a clean and accurate cut. The laser beam is controlled by computer programming, allowing for intricate and complex designs to be cut with ease.

Metal laser cutting machines, also known as (computer numerical control) CNC laser cutting machines, are available in three main types: CO2 laser cutting machines, fiber laser cutting machines, and Nd: YAG laser machines. You can learn more about how laser cutting of sheet metal works. These machines use a laser cutting head to send a focused laser beam through a focusing lens to precisely cut sheet metals based on specific purposes and materials.

Compared to other thermal cutting methods like plasma cutting machines, laser cutting offers numerous advantages, such as high precision, minimal material wastage and heat affected zone, and the ability to cut a wide range of materials. The laser cutting process is not only faster, but also produces cleaner cuts, reducing the need for additional finishing work, and making it a popular choice in the manufacturing and fabrication industry.

The Role of Laser Cutting in Sheet Metal Fabrication

Laser cutting, particularly with fiber lasers, plays a crucial role in manufacturing sheet metal. It allows for precise and efficient cutting of metals into desired shapes and sizes. Fiber lasers employing a fiber optic cable, are highly versatile and can handle various thicknesses and types of metals, including steel, aluminum, and stainless steel. Laser cutters are commonly used in the production of components and parts for industries such as automotive, aerospace, electronics, and construction.

Laser cutting is a crucial technology in the manufacturing industry, allowing for the precise fabrication of complex designs in steel. It enables the efficient production of high-quality metal components through its cutting accuracy and ability to combine with other processes like bending, welding, and finishing. Laser cutting is especially valuable in sheet metal cutting fabrication, ensuring the creation of intricate and precise finished products.

Key Factors to Consider When Choosing Your Machine

Here are five things to consider when choosing equipment for your sheet metal business, specifically for working with steel and other metals. Make sure to evaluate the capabilities of the laser cutting machine and its compatibility with different materials.

Power and Speed

The power rating of laser cutting equipment for sheet metal is an important consideration. The laser cutting speeds should neither be too fast nor too slow, as this will affect the quality of the cut. The higher the laser power, the faster and more efficient the cutting process will be. Look for a CNC metal laser cutter with high power laser beams to ensure quick and precise cuts.

Material Compatibility

Consider the types of metals, such as steel, you plan to work with when choosing an industrial laser cutting machine. Different machines may have limitations on the thickness or type of material, like carbon steel, they can cut effectively. Make sure the laser cutter you choose is compatible with the sheet metal you’ll be working with.

The fiber laser machine can be adapted to different metal thicknesses, cutting materials like thin materials. Click here to learn about the fast laser cutting of thin metal.

Precision and Accuracy

Precision and accuracy are crucial in the laser cutting process. Look for appropriate laser cutters that offer advanced fiber laser technology and features such as auto-focus capabilities or optical recognition systems. These features will help ensure that your cuts are clean, accurate, and consistent. Consider using professional laser cutting services for the best results.

Safety Features

Safety should always be a top priority when operating lasers for cutting metal workpieces. Look for laser cutters that come equipped with safety features such as emergency stop buttons, protective enclosures, or automatic shut-off systems. These features will help protect both operators and equipment from potential hazards during the process of cutting and engraving metal.

Cost and Value

Lastly, consider the cost and value of the sheet metal laser cutter machine you’re considering. While it’s important to find an industrial laser cutting machine within your budget, also take into account its long-term value in the cutting process. Look for machine tools that offer a good balance between cost-effectiveness and quality performance with laser focus in processing.

Advantages of Baison Laser Cutting Machines

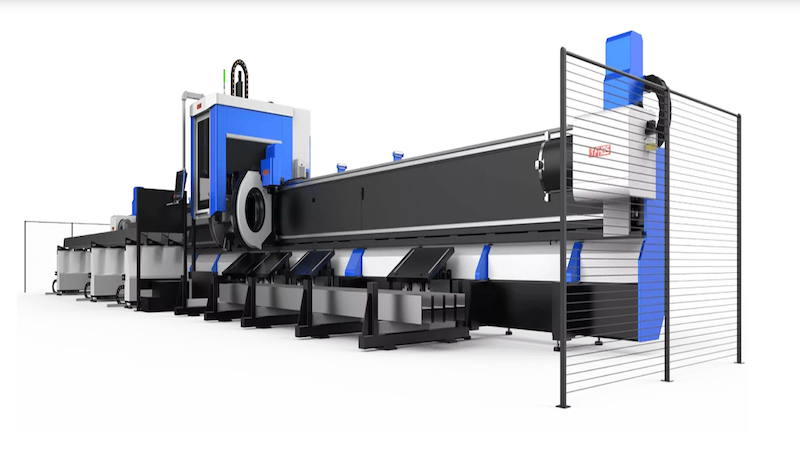

Baison is one of the best laser cutting machine manufacturers in the world. Baison laser cutting machines are designed for precision cuts and engraving on various workpieces. These machines utilize advanced control systems, making them easy to operate and offering programming flexibility.

With exceptional performance in sheet metal fabrication, Baison lasers are a top choice for high-quality results. The key advantages of Baison laser cutting machines include.

Advanced Technology for Superior Performance

Equipped with advanced laser technology, Baison laser cutting machines deliver superior performance in terms of accuracy, laser cutting speed, and efficiency. These machines ensure precise cuts in sheet metal fabrication processes, delivering accurate results with exceptional quality for engraving and working on the workpiece.

The laser cutter delivers higher cutting speeds without compromising the quality of cuts. They can efficiently handle various metals, providing quick turnaround times for projects. We utilize state-of-the-art laser engraving features that enhance the overall cutting process.

Reliable and Durable Construction

Baison Laser Cutting Machines are built to withstand the demands of industrial cutting operations. They are manufactured with high-quality materials and designed for robustness and durability. The construction of these machines ensures their longevity and minimizes downtime due to maintenance or repairs. By investing in a reliable and durable machine, users can trust that their production process will remain uninterrupted, thereby increasing overall efficiency and profitability.

Exceptional Customer Service and Support

Baison prioritizes customer satisfaction by offering exceptional customer service and support to its clients. Our dedicated team of experts is available to provide assistance with machine setup, operation, and troubleshooting. Whether it’s technical advice, maintenance guidance, or spare part replacement, Baison ensures that customers receive prompt and effective support. This level of customer service helps users maximize the potential of our laser cutting machines and minimizes any disruptions to their operations.

Sheet metal laser cutting machines have revolutionized the manufacturing industry, offering efficient and precise cutting solutions. The suitable machine choice depends on specific requirements, budget, and future growth plans. Baison fiber laser cutting machines provide reliable options for those seeking high-quality performance and long-term durability.

FAQs

Can I use a metal laser cutting machine for materials other than sheet metal?

Yes! Cutting non-metallic materials and metal materials such as acrylic, wood, plastic, and more is easy for fiber laser cutting machines. These laser machines utilize fiber lasers to make precise cuts.

How accurate are metal laser cutting machines?

Metal laser cutting machines offer high precision with tolerances as low as 0.1mm depending on the model and settings.

Can I cut complex shapes with a metal laser cutting machine?

Absolutely! Metal laser cutting machines can effortlessly cut intricate and complex shapes in metals, allowing for limitless design possibilities.

Concluding Thoughts

Investing in a sheet metal laser cutting machine can significantly enhance productivity and competitiveness in industries that work with metals. These machines deliver exceptional results by effectively cutting intricate details with a reflective nature, making them ideal for working with various types of metals. Additionally, they ensure a smooth surface finish that meets high standards for metals.

When considering sheet metal laser cutting, it’s crucial to understand the procedures involved. These machines employ advanced techniques to process the workpiece without compromising its structural integrity or creating excessive heat. By running test runs and fine-tuning the settings, operators can optimize their processes for maximum efficiency.

It’s important to note that while sheet metal laser cutting offers numerous advantages, there are some disadvantages as well. For instance, certain types of materials may not be suitable for this technique due to their reflective surfaces or inability to withstand the intense heat generated during the process.

Baison Provides Top Laser Cutters

Baison Laser Cutting Machines stand out from the competition due to their exceptional quality and reliability. With advanced features and robust construction, Baison machines deliver outstanding results time after time. Whether you’re a small business or an industry leader, Baison has a solution tailored to your specific requirements.

The purchase of such a machine can be an overwhelming task. It’s not just the initial price you pay, if the wrong equipment is chosen, you have to live with the decision for quite a long time. Don’t miss out on the opportunity to revolutionize your sheet metal entire manufacturing process with Baison’s fiber laser cutters and the CO2 laser cutting machine. Get a free sample proofing today and discover how our machines can transform your business.